| Philips

Vesta (PCVC675) LONG EXPOSURE cooled SC2 camera A,

Introduction

B,

Technical data

C, Peltier cooling system power

requirements

D, Detailed photo-documentation of

modification

E, Electronic thermostat

Introduction

After five months of using my Philips

Vesta 675SC camera I decided to modify it to stage 2 (software

switching long exposure mode, switching CCD amplifier on/off)

with cooling. The inventor of this modfication is Steve

Chambers and you can find on his pages schematic

diagram and information about this modification. The

cooling system was built according to nice idea of Peter

Vasey.

!WARNING! You can use the following

information on your own risk. Author is not responsible

for any damage of camera or computer equipment. The

following procedure was done successfully by author, but

he cannot guarantee, that your modification will be

successful.

Technical Data

Weight

(incl. USB cable) |

309g

(non modified Vesta has 175g)

|

Dimensions

(length x width x height) |

90mm x

65mm x 40mm (without radiator)

90mm x 65mm x 80 mm (with radiator) |

| Maximum usable exposure time |

15-20

min |

Temperature difference

(difference between ambient temperature

and temperature of alloy chamber arround CCD) |

~28°C |

| Cooling down time |

8-10

min |

DarkFrame

(15min, gain 100%, white balance - Indoor,

cooled, ambient temperature 25°C) |

|

Peltier Cooling System

Power Requirements

Peltier unit - Supercool

PE-127-10-25

| Imax |

2.0 A |

| Umax |

16.4 V |

| PCmax |

19.3 W |

| DTmax |

74 °C |

| THot max |

80 °C |

Dimensions

(l x w x h) |

30mm x 30mm x 4.8mm |

|

| Voltage |

Current consumption |

Power consumption |

| 12V |

1.26A |

15.12W |

| 9V |

0.96A |

8.64W |

| 6V |

0.63A |

3.78W |

| 5V |

0.46A |

2.30W |

| 4.5 |

0.39A |

1.75W |

Note: Power consumption was measured with

ventilator switched ON.

Detailed photo-documentation of

modification

Detailed description of procedure of modification

camera for Peltier cooling you can find on Peter

Vasey web site.

Here you can find detailed photos, which illustrate, who

the modifaction was done.

Alloy casting housing the LED, Microphone, CCD

Chip and lens. Note that end part of PCB carrying

only model information was trimmed off. |

Detail view of alloy part, which must be cut down

to cube. |

Truncated PCB with CCD, microphone and LED.

The with of module is 20mm. |

Another look at CCD. The second pin from left

must be cut. |

Detail of hand-worked alloy part. Abrasive paper

'400' was used for final treatment. |

Detail from PCB side. Note the small recess on

the left side which has been cut to allow the

passage of a wire from cut CCD pin 9. |

Another side of alloy part. The recess is for

microphone. |

Hand-made aluminium parts for cooling system

together with alloy box. |

Detail vie of aluminium plate, which is connected

to cold side of Peltier unit |

Small spacer between aluminium plate and alloy

box. |

Small clamping plate for gripping alloy box to

aluminium plate. |

Peltier module (Supercool PE-127-10-25) |

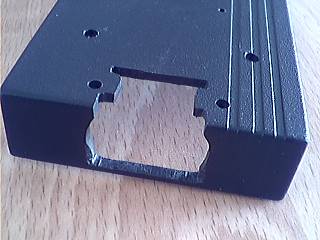

Top view of plastic case with filed out openings. |

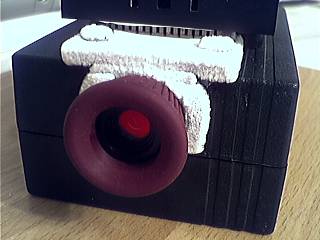

Front view of plastic case with detailed view of

opening for alloy box with CCD unit. |

Aluminium plate attached to plastic box |

Cold plate with Peltier unit. Note black plastic

spacers on both sides of aluminium plate. |

View from inner part of plastic case |

Gripping of alloy box part by means of clamping

plate and bolts |

Rear side with holes for connectors and LED |

Cut pin 9 of CCD.

Unfortunately, I had a bad day - I cut the pin 13

accidentally. You can see repair on right side |

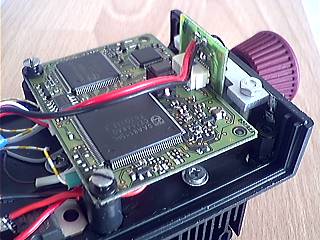

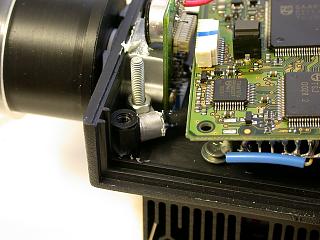

Camera's main board mounted into case |

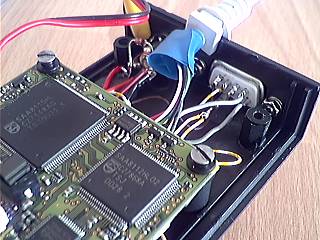

View of connector part situated on rear side |

Top view of inside parts |

Switching transistor of SC2 modification is

soldered directly to CCD's PCB (prevention from

unwanted interference). Note green 2k7 resistor |

| |

|

Metal part from Vesta camera with tripod thread

was modified for attaching to bottom part of case |

Bottom part of case with tripod thread |

The final result |

Rear side of camera - green LED (from CCD PCB),

connector for 12V power for Peltier unit and

ventilator, CANON 9 connector for computer

control and USB cable |

Detail of Peltier unit with radiator |

Ice created on cooled metal parts after 1 hour of

cooling. (Ambient temperature 26°C) |

Electronic thermostat

The Peltier cooling system of my webcam

is able to generate temperature difference about 28°C (between

ambient temperature and temperature of cold chamber). It

is very powerful cooling. But there may be a problem in

colder nights, when cold chamber can become too cold. In

freezing nights it is not a problem to get tempereture of

-30°C or even lower, which is even under allowed storage

temperature!

According to SONY datasheet the CCD chip used in Philips

Vesta cameras (ICX098AK) has the following temperature

conditions:

| Storage temperature |

–30°C to +80°C |

| Operating temperature |

–10°C to +60°C |

I decided to design an electronic

thermostat, which would protect the CCD from very low

temperatures.

The thermostat should satisfy the next demand:

1, Low power loss (i.e. low production of heat)

2, Small size and weight - the best solution would be to

put the electronics into camera case

3, Adjustable temperature threshold

4, Precision about +/-1°C

The most difficult criteria are 1, and 2,. The problem is

to switch the current about 1-1.5A without loss of power.

I tried several solutions - bipolar switching

transistors, relays - but without success. In case of

inbuilding thermostat in camera case, it is unwelcome for

electronics to generate additional heat. Finally I

decided to use power MOSFET. The IRFR024N type has the

resistance in on-state 0.075Ohm. It enables to achieve

power loss only 75mW (1A current).

The costs of the whole electronic thermostat is not more

than 5,-Euro.

Here is my final version of thermostat for Peltier

cooling system:

Click the

picture to see full-sized schematic diagram.

Note: Supply

voltage is 12V. Inputs of the second operational

amplifier must be handled (+ input to VCC, -

input to GND) to avoid its oscillation. |

The principle of function:

The temperature sensor IC2 (LM335) generates voltage

which represent temperature (10mV/K). The voltage from IC2

is compared with voltage adjusted by R8 trimmer. IC3a (one

half of LM393) serves as comparator. R11 and D1 provide

hysteresis of the control loop. The hysteresis is

necessary for securing the transistor T1 (IRFR024N) is

working in switching mode (only in this mode the power

loss is very low). D2 LED is indicating that Peltier is

switched on (I like blue LED for indication of cooling ;-))).

The contruction notes:

I built the module on experimental piece of PCB. I

protected the temperature sensor from water/ice by

putting its end with pins into heat-retracting insulator

(see a picture below). The voltage from IC2 is led out to

connector on rear camera panel. It enables me to measure

temperature of cold chamber.

As the thermostat consists of the sensitive measuring

part and power switching part, the PCB must be carefully

designed. You must pay attention for current loops - you

have to design two separate grounds for each part. In

case of violation of this rule, the thermostat will not

be sufficiently accurate.

The adjustment procedure:

At first it is necessary to do fine

adjustment of IC2. I used mixture of water and ice (which

has temperature 0°C while ice is not melted). I put the

temperature sensor into this mixture and by means of

trimmer R7 I set the voltage on the IC2 (between cathode

and anode) to 2.731V (which represents 273.1 Kelvins).

Then I set the voltage in R8 trimmer according to

required temperature - in my case I set 2.551V, which

represents -18°C. With current values of R2, R4 and R8

it is possible to set the temperatures between -19° - +2°C.

That's all.

According to my tests the termostat is holding the

temperature in required range -18° +/-1°C.

And here are some photos of implementation of the

thermostat:

The temperature sensor (LM335) put into heat-retracting

insulator |

The holder of temperature sensor (made from piece

of plate) with hole for M3 bolt |

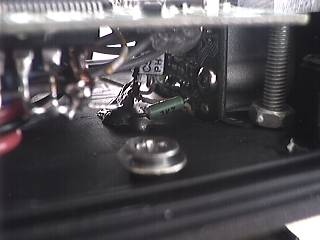

The thermostat electronics built in bottom side

of camera's case |

Fixation of sensor to cold chamber. The sensor is

fixed under M3 nut. |

The rear panel of camera. Notice the bottom part:

On the left side there is a blue LED (Peltier

indicator) and on the right side there is a

connector for measuring temperature (by means of

digital multimeter). |

|

Have

a look at tests of my cooled SC2 camera

Back to Astro Photography

page

Computer generated images,

real images, drawings and texts are property of the

author and may not be reproduced or used without

permission of author.

Last Update: 14.09.2005

|